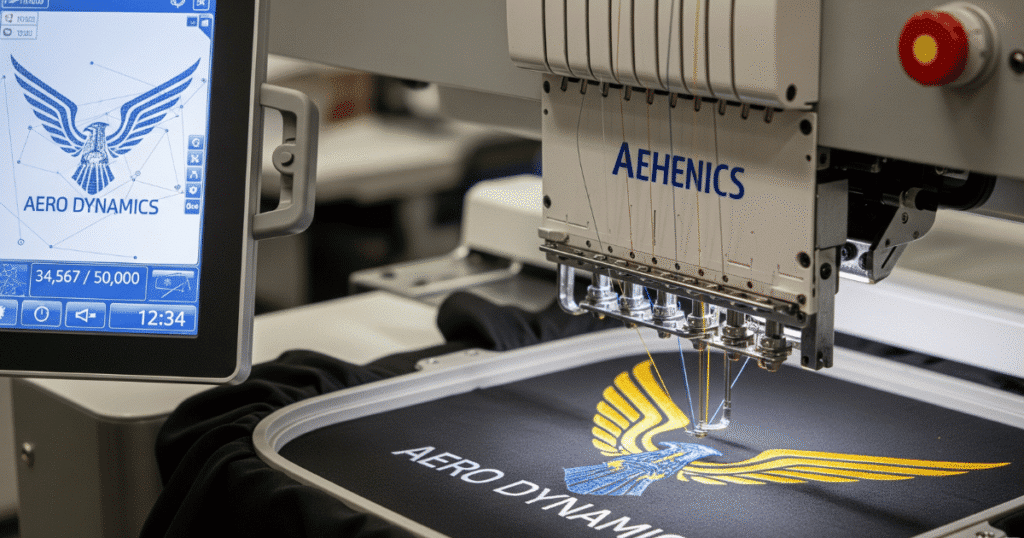

When Nina first started her small home-based embroidery shop, she expected all her problems to be about thread tension, machine settings or fabric shrinking. What surprised her most was that the real challenge came before a single stitch even dropped. She soon realized that no matter how shiny the threads were or how advanced her machine seemed, the final result always depended on the quality of the digital file instructing the machine. After using several auto-digitizing programs and wasting shirts and money, she turned to specialized customized embroidery digitizing solutions and finally her logos stitched clearly, text looked legible, and clients stopped complaining. That first high quality file completely changed her embroidery workflow.

In this article you will learn how customized digitizing is different from generic digitizing, how it solves real production problems, where custom embroidery digitizing brings the most value, what techniques professional digitizers use, why many small or mid-sized brands depend on digitizing services, and how proper stitch file setup prevents wasted time and material. For many modern embroidery businesses, these solutions are not a luxury but a necessity. One place many small business owners rely on for technical work like custom embroidery digitizing is linked later in this article with the correct anchor.

What Customized Digitizing Means in Practical Terms

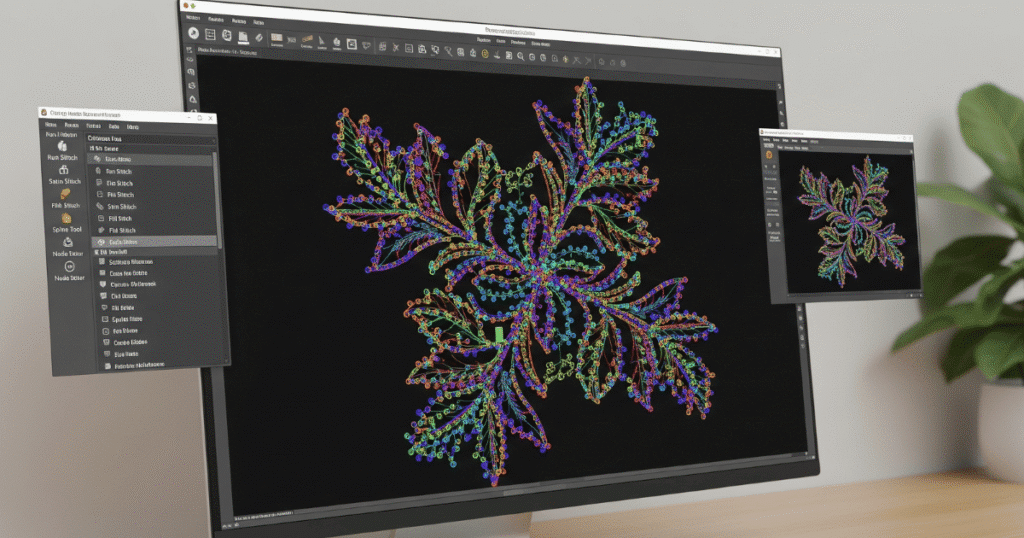

Customized digitizing means the digitizer creates a stitch plan based on the specific fabric, logo style, purpose, and machinery. Instead of using automatic conversion tools that may create massive density or place stitches without understanding thread pull, a real digitizer decides which parts should be satin, which should be fill, how to apply underlay, how to compensate for shrink or distort, and how to avoid overlapping fills. This is completely different from pressing a button in a software tool.

These types of customized embroidery digitizing solutions are built to predict the machine movement in real life conditions. Stitch angle changes are placed where the fabric flexes. Underlays are set lightly on stretchy fabrics like polo shirts so they don’t pucker. On rigid caps, extra support might be added to help letters stay upright. This is what makes the final product look professional and consistent across different garments.

Difference Between Custom Embroidery Digitizing and Generic Files

Generic digitizing usually means the file has been made with no knowledge of the final use. A stitch file that looks fine on a denim may entirely distort on a knit beanie or towel. Generic files often ignore density adjustments, pull compensation, or push-pull effect which makes the stitching narrow or wide. In contrast, custom embroidery digitizing looks at the artwork, selects proper stitch types for each shape, chooses the right angle to minimize glare or shine, and tests it on the actual fabric type if possible.

Professionals often request the size of the design, the fabric type, and machine brand before starting the work. They might simplify very thin lines because thread cannot physically produce them at a small scale. They might convert gradient areas into layers of lighter fill with different angles to give a textured effect. This level of planning is what transforms a flat logo into a beautiful embroidery piece.

Process Involved in a Professional Digitizing Service

A high quality digitizing service often follows a series of steps:

- Artwork cleanup and vector conversion if required

- Segmenting design into stitch types

- Assigning proper stitch angles

- Adding proper underlay for stability

- Adjusting density based on thread width and fabric type

- Applying pull compensation

- Planning sewing sequence to reduce trims

- Exporting to required format (DST PES EXP etc)

- Running a physical stitch test in some cases

Once the test is done, minor tweaks are made to fix any pull or gaps. Only after confirmation the file is supplied to the customer. This systematic process ensures that the machine will run smoothly, which saves time during production.

How Good Digitizing Saves Money

Many people assume digitizing is just the first step before stitching, but it also impacts cost deeply. When a file is not properly digitized, something small goes wrong during production such as thread breaks or recurring needle issues. This leads to wasted blanks, wasted thread, operator frustration and machine downtime. Proper digitizing reduces thread consumption, speeds up average production time, and avoids wastage.

If a company schedules a batch of one thousand hats and starts with a badly digitized file, they may end up redoing the hats or paying extra workers to fix the errors. On the other hand, a well made file with optimized path can run smoothly across multiple heads with fewer interruptions. This difference in productivity is the real hidden cost that many business owners only discover after they switch to a better file.

Market Need for Customized Embroidery Digitizing Solutions

According to industry studies from Research and Markets as well as surveys from apparel decoration forums, there has been steady growth in demand for embroidery services in North America and Europe. Brands want unique custom stitching. Specialty techniques like puff, applique or chenille also require precise custom digitizing. Because more small businesses enter the embroidery sector, the need for specialized digitizing services grows. An automatically generated file can make an embroidery business lose clients due to poor output, so many shops outsource digitizing as a strategic partnership.

Many small print shops and apparel startups do not have time to learn the complex software. They outsource digitizing regularly to professionals who provide custom embroidery digitizing because they trust that a good file keeps their reputation strong.

When to Use Customized Digitizing Over Auto Tools

- Small text or fine detail under half an inch

- Curved surfaces like caps or cylindrical items

- Puff embroidery that needs foam

- High value items that must be precise

- Multi color designs that include gradients or shading

- Applique or layered fabric projects

Auto tools may still work for very basic block shapes or one color fills for personal hobby use. However, for commercial grade output, customization makes a visible difference in stitch balance and overall realism of the design.

Benefits to Brands and Designers

When a designer delivers a well digitized file to a manufacturer, it is more likely that the manufacturer will produce a result that matches the brand’s standards. This gives consistency across multiple production cycles. Many fashion or sports brands rely on this consistency to keep their brand identity intact. Consumers notice differences even if the brand thinks it is minor.

Digitizers who specialize in customized embroidery digitizing solutions help preserve the designer’s vision while making it appropriate for machine embroidery. This requires both artistic understanding and technical understanding. A good digitizer bridges those two roles.

One Brand Mention Example

One well reviewed provider that many business owners choose for reliable custom embroidery digitizing is True Digitizing due to their structured process and willingness to adjust files based on fabric.

Challenges Solved by Custom Digitizing

Errors like puckering on knit shirts, shifted outlines on hats, broken threads on heavy canvas, twisted text edges on stretchy fabric are all often traced back to poor digitizing. These problems are solved by using custom files that have density control, underlay and compensation built for that fabric. Another benefit is that custom digitizing often includes color stops organized in a way that reduces excessive thread changes which improves production efficiency.

Artwork Preparation for Better Digitizing Results

Sending clean artwork helps the digitizer provide a cleaner stitch plan. If the original artwork is pixelated, has gradients with no clear edges, or has extremely small details (like tiny strokes or micro text), the digitizer may need to simplify it manually. If possible, sending files like AI, PDF vector or SVG helps a lot. This results in better stitch simulation and faster turnaround.

Client Case Story

A small sports team ordered custom jerseys with logos. They used a free online digitizing tool to create the file, and the results on the jerseys looked uneven after washing. They decided to invest in customized digitizing. The new file not only stitched cleanly but had more dimension and durability after several washes. They also noticed that production time was reduced by nearly fifteen percent because the machine did not stop to fix thread breaks. That switch increased their profit margin on each jersey, proving that quality digitizing pays off.

Why Every Embroidery Business Should Consider Customized Digitizing

Even small one person shops gain a lot from proper digitizing because it reduces trial error time. Imagine wasting two shirts just to get one decent result. That cost quickly builds up. Instead with a balanced stitch file, you can say yes to more orders with confidence that the output will look good. This is especially important when dealing with return customers because they expect consistency.

How Custom Digitizing Supports Scalability

As a business grows, having consistent digitized files means the brand can scale production, use different factories or machines without redesigning the file. They can store the master file and use it whenever needed. This level of repeatability is essential for larger orders and for building a reputable brand.

Closing Thoughts and Practical Advice

Investing in digitizing is an investment in every product you produce. Things like thread, stabilizer and machine speed all matter, but without a solid stitch map, none of those can fix a distorted output. With the right digitizer and a structured file creation process, embroidery becomes easier, more stable, and more profitable.

Will you choose customized embroidery digitizing solutions from experienced professionals to improve your next run?